250516

コンバーテック

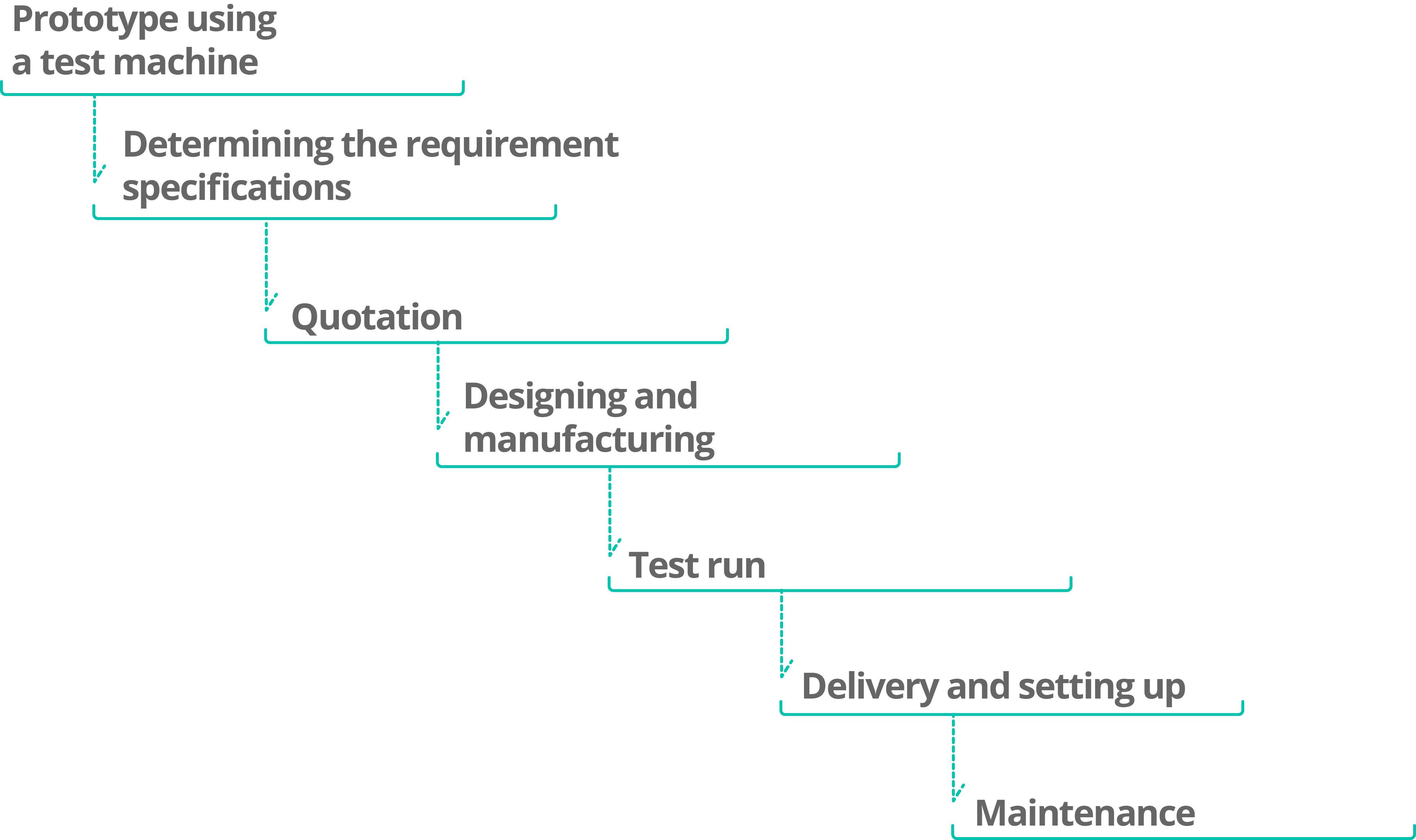

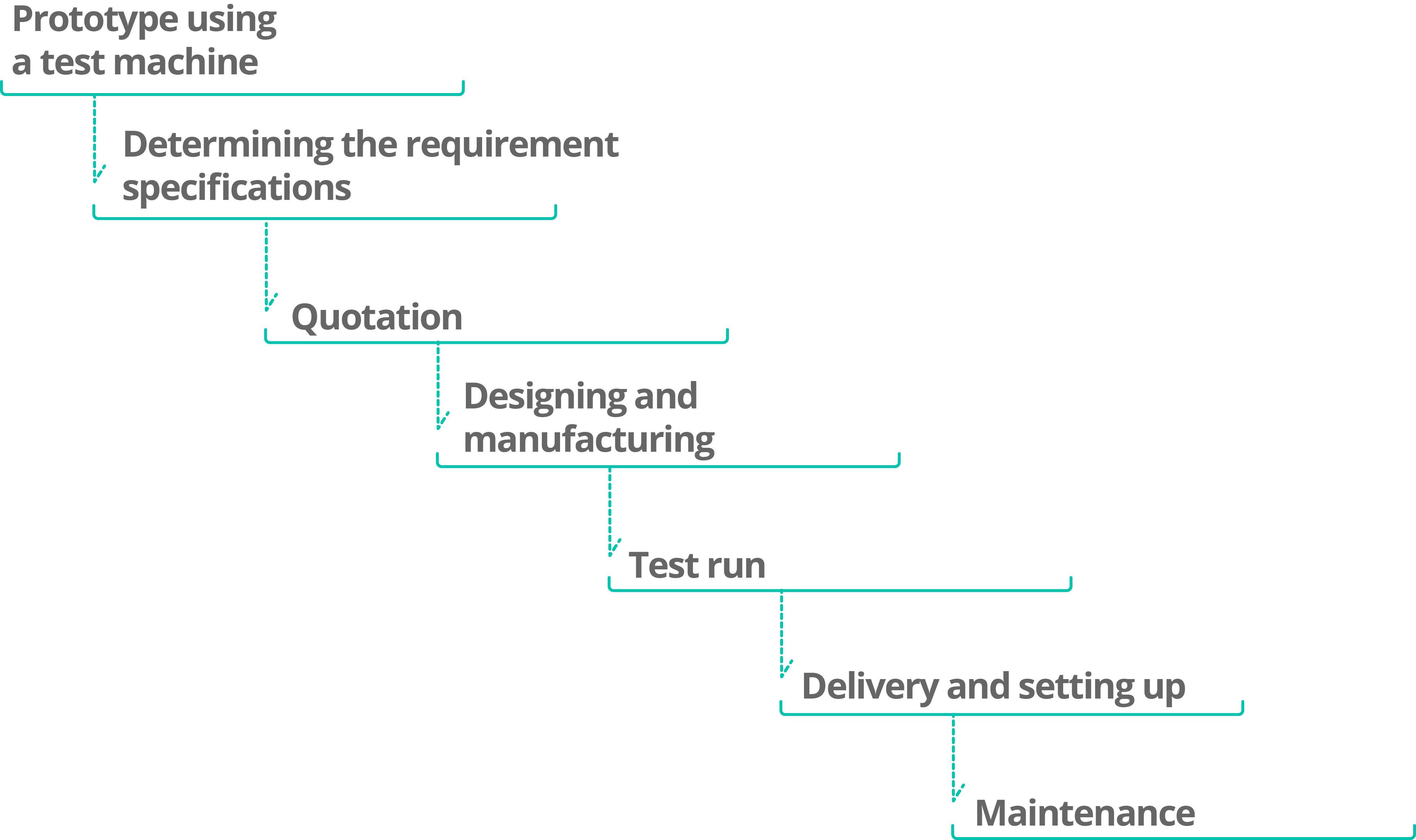

The Isobaric double belt press uses a unique sealing system to pressurize, heat, and cool the workpiece while transporting it between the upper and lower belts. This enables continuous production, which is not possible with a conventional batch system, and results in improved productivity and cost reduction.

Since the Induction heating method can apply heat directly to the belt, the heat-up time is shorter than that of machines that use hot plates or heat transfer oil, contributing to more efficient heating. Another advantage is that it has less effect on the temperature of the peripheral parts around the belt.

It is our top priority to listen to the needs of our clients, enabling us to work together to propose further improvements, such as downsizing, weight reduction, and detailed customization through the latest technology.

~10MPa *note

~400℃

80℃~

~15m/min

~1500mm

While the general roller type presses use "linear pressure" to make materials, our Isobaric double belt press with its unique sealing system can apply "surface pressure", which greatly increases the pressurized area.

The above figures are for reference only. They may vary depending on your needs and design.

We strive to optimize

the heating and cooling

efficiency of our machines.

We achieve high

maintainability

by reducing the number of

parts in our machines.

We use computer-aided

structural analysis

to increase the operational

life span of our machines.

In addition to the isobaric double belt presses, we also design and manufacture a variety of other equipment.

We also provide maintenance services for production equipment, mainly for paper mills.

Please contact us >here for details.

68 Higoshiyama Saimi-cho Anan-shi Tokushima,Japan

TEL.0884-23-2850 FAX.0884-23-2588

>Google Map127 Minamisuji Fukumura-cho Anan-shi Tokushima, Japan

*If you have any questions, please contact the head office.